Pulp

Pan Pac has been producing pulp in Hawke's Bay for nearly 50 years.

We have a wealth of knowledge and depth of experience across all facets of our integrated supply chain.

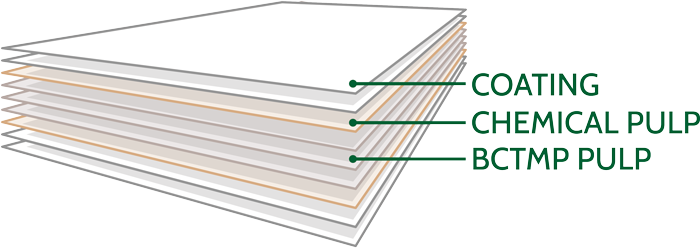

In our Pulpmill, we produce Bleached Chemi Thermo Mechanical Pulp (BCTMP), as the preferred furnish for our customers in a wide range of board, towelling and paper products. The large and bulky fibres of Radiata Pine offer pulp properties that optimise the quality of the finished product, particularly for manufacturing board grade products.

Prior to 2012, Pan Pac produced only TMP (Thermal Mechanical Pulp), which was used mainly for newsprint. Foreseeing the decline in newspaper sales worldwide, Pan Pac diversified by building a state-of-the-art screening and bleaching plant to produce BCTMP.

In July 2021, Pan Pac reduced production of TMP significantly and now primarily produces BCTMP.

"Our Pulpmill produces up to 850 tonnes of quality BCTMP pulp daily."

Market Scope

We sell our BCTMP grades in New Zealand and all over the world.

Our current international markets include Australia, China, Indonesia, South Korea, Japan, Malaysia, Taiwan, Vietnam, India, Pakistan and South Africa.

Pan Pac has authentic relationships with professional marketing agents in each country of destination.

Energy

Energy efficiency is important to us

The pulp making process is energy intensive, so managing energy efficiently is a critical part of our business. We do this by generating thermal energy from our two biofuel boilers, which is used for both pulp and lumber drying.

Waste to energy

Most of our thermal energy is generated from burning waste in boilers to produce steam. The waste includes bark, sawdust, shavings, chip fines and waste water. Using our waste in this way minimises the need to put it to landfill. We use natural gas to meet the remainder of our thermal energy needs.

Because energy from the boilers is all generated from biofuel – it is neutral in terms of CO2 Kyoto emissions. In addition, it contributes to nearly 40% of Pan Pac’s total energy usage, and meets up to 12% of our electricity needs.

Water

Our water is sourced from the Esk River and is used many times within the mill.

Before discharging our wastewater, we put it through the dissolved air flotation process. Then, it goes through a two-stage biological treatment process. By the time it leaves our site, we have ensured that we have removed as much of the suspended solids, resinous material, and biologically degradable material as we can.

"We manage our wastewater properly."

Fibre Supply

Our Fibre Supply group coordinates the delivery of woodchip for pulp production. Fibre Supply includes whole log chipping, chipped residuals from Pan Pac’s sawmill and purchased wood chips from other regional sawmills.

Our Chipmill manufactures up to 450,000 tonnes of wood chip a year from whole logs.

These chips are blended with others to get optimal properties for the pulping process.

Quality is as important to us as it is to our customers

We pay special attention to our Critical Control Elements to ensure quality and consistency. These include minimising chip age, blending the various supplies and screening to remove oversized chips and fines.

We do not waste resources at Pan Pac

Bark and fines generated by the Chipmill are utilised for boiler fuel.